People who love high-performance cars know a lot about horsepower and torque. Diamond collectors understand the value of the “4Cs”: cut, clarity, color and carat. And if you’re in the market for fine furniture, you’ll find it helpful to know the advantages of quarter-sawn wood. That’s what Quarter-Sawn Lumber: More Stability, More Beauty is all about.

Quarter Sawn Mystery Revealed

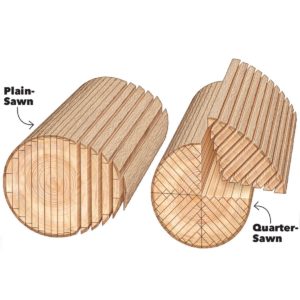

If you’ve heard or read sales pitches about furniture, you’ve most likely come across the term, “quarter-sawn” to describe wood – such as “quarter-sawn white oak.” So what does quarter sawn mean? And, more importantly, why does it matter? A tree’s annual rings, species, imperfections such as knots and the cut of the board have everything to do with the appearance of wood in furniture. Craftsmen usually cut boards along the length of the log. Two of the main ways they do this is plain sawing and quarter sawing.

Plain-Sawn: More Boards, Great-Quality Lumber

Plain sawing means slicing the log into boards of equal width across the entire log. With the plain-sawn cut, the tree’s annual rings run roughly in the same direction as the cut of lumber at the outer ends of the log. This explains the wavy woodgrain pattern of some plain-sawn lumber. Meanwhile, the annual rings are at about a 90-degree angle (when viewed from the end) of each board cut from the middle of the log. Of course, the lumber cuts from between the ends and the middle have the annual rings at varying angles. Plain-sawn is the fastest and easiest way to cut lumber. Also, it results in minimal waste. So it’s the least expensive cut of lumber. Cabinetmakers use plain-sawn lumber — like oak, maple, and cherry — to build furniture.

Quarter-Sawn: Less Boards, Superior-Quality Lumber

The quarter-sawn cut means that the log is first sliced into four wedges lengthwise. (Hence the name quarter-sawn.) Then, boards are cut in equal widths running from the center of the log toward the bark. As a result, the annual rings intersect each board between a 60 and 90-degree angle. This cut results in more waste. So quarter-sawn lumber is more expensive than plain-sawn lumber.

Quarter-Sawn Lumber: More Stability, More Beauty

The special nature of the quarter-sawn cut gives the lumber some distinct advantages. Quarter-sawn wood resists warping and splitting. It’s also more stable than plain-sawn wood. What’s more, quarter-sawn wood expands and contracts less than plain-sawn wood. Because of its strength and stability, furniture builders and cabinetmakers use quarter-sawn wood for items of fine furniture. Also, you’ll find quarter-sawn wood in the neck and fretboards of expensive string instruments.

In addition, quarter-sawn wood has a straighter, more even grain pattern than plain-sawn wood. This is because the lumber shows the side view of the annual rings. Also, quarter-sawn lumber reveals the wood’s ray cells which display a wavy, ribbon-like pattern called ray fleck. This is why cabinetmakers use quarter-sawn wood for decorative paneling and fine furniture.

Amish Furniture Built with Quarter-Sawn Wood

Weaver Furniture Sales in Shipshewana, Indiana, offers a wide variety of solid hardwood, Amish furniture. Many of the pieces are built with quarter-sawn hardwoods like oak, cherry and maple. You can explore the collection of quarter-sawn furniture by visiting Weaver Furniture’s website. Or, check out Weaver Furniture Sales in person by visiting their ‘brick and mortar’ store in Shipshewana, Indiana.